Cleanrooms for Manufacturing

Why Use a Cleanroom for Manufacturing?

Precision matters in manufacturing. A speck of dust ruins a circuit board. Static discharge damages sensitive components. Temperature swings throw off tolerance specs during CNC machining.

Cleanrooms give you control over these variables without shutting down production lines or building permanent infrastructure. Modular systems deploy around existing equipment, creating contamination-controlled zones where quality and compliance requirements demand them.

Limit Contamination

Reduce airborne particulates from personnel, machinery, and ambient environment.

Control Airflow & Pressure

Prevent cross-contamination between production zones and maintain consistent environmental conditions.

Enhance Safety

Isolate noisy equipment, contain hazardous processes, or protect sensitive operations from ambient conditions.

Real-World Uses for Modular Manufacturing Cleanrooms

From full production suites to micro-zones around a single CNC machine, modular manufacturing cleanrooms adapt to manufacturing floor realities. Here’s where they make the biggest operational impact.

-

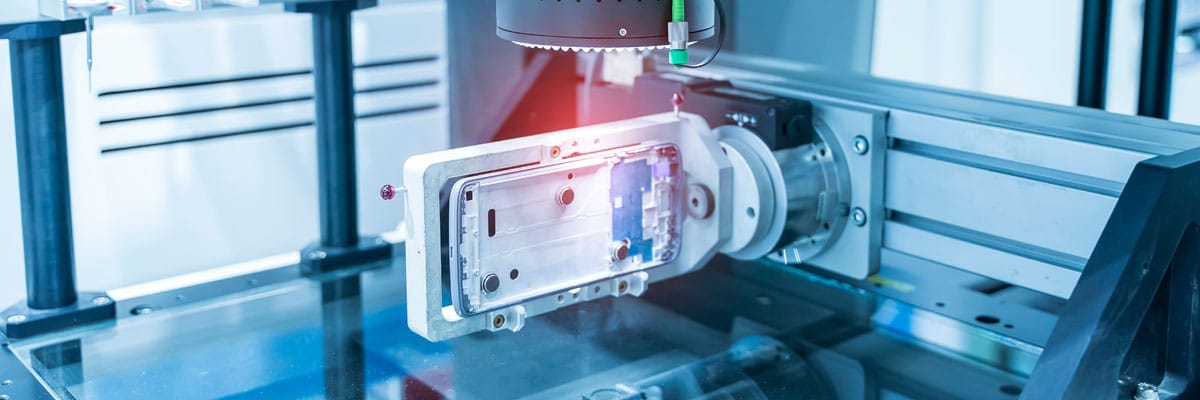

Electronics Assembly

Electronics Assembly

ESD-safe environments for circuit board assembly, semiconductor handling, and component testing. Control static discharge while maintaining contamination standards that prevent product failures and warranty claims.

-

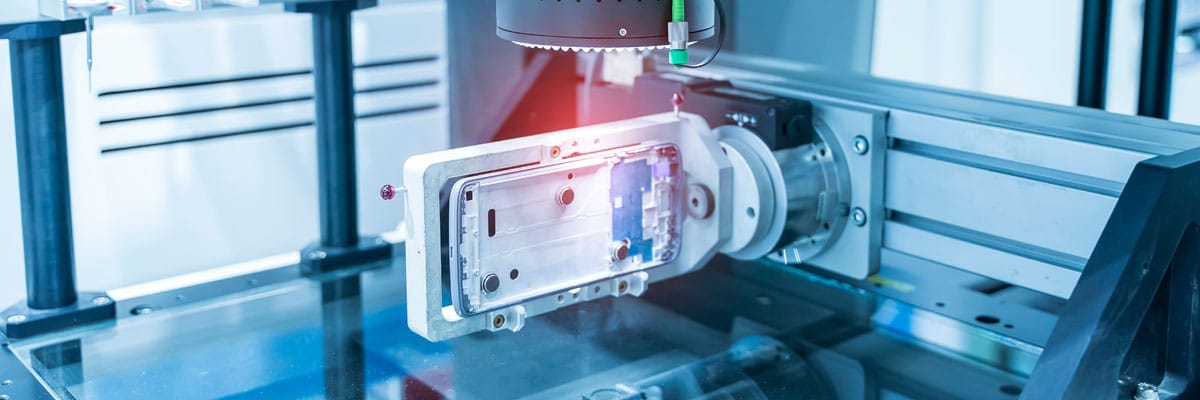

CNC Machining

CNC Machining

Dust containment and sound mitigation for precision machining operations. Protect finished parts from airborne particulates while reducing noise exposure for operators. Maintain dimensional accuracy on tight-tolerance work.

-

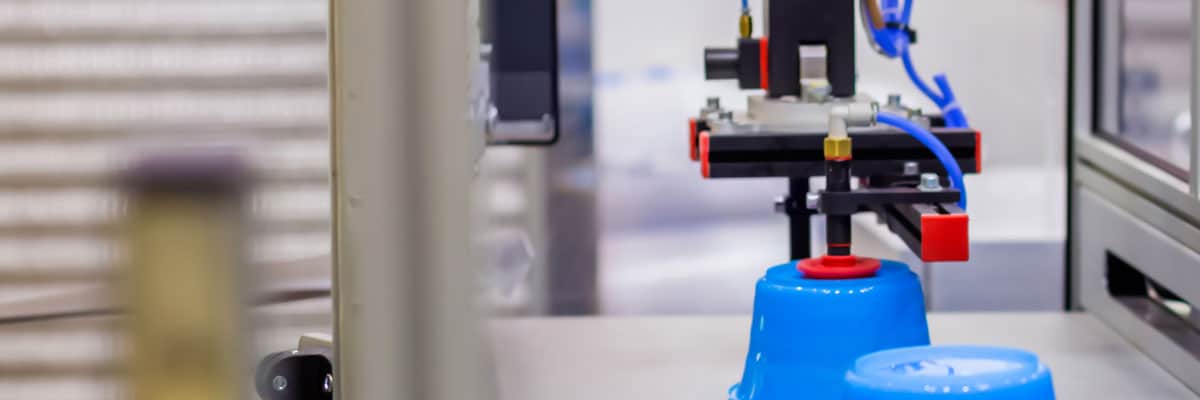

Injection Molding

Injection Molding

VOC and particulate control for plastic molding operations. Capture fumes at the source, protect finished parts from contamination, and maintain air quality standards for personnel working near hot processes. compliant with current FDA regulations.

-

Medical Device Packaging

Medical Device Packaging

ISO-classified environments for final packaging and sterilization. Meet FDA requirements without overhauling entire facilities. Deploy compliant clean space exactly where packaging operations occur.

-

Additive Manufacturing & 3D Printing

Additive Manufacturing & 3D Printing

Contamination control for powder-based processes and post-processing operations. Contain ultrafine particulates from metal printing, protect sensitive resin operations, and maintain air quality during finishing work.

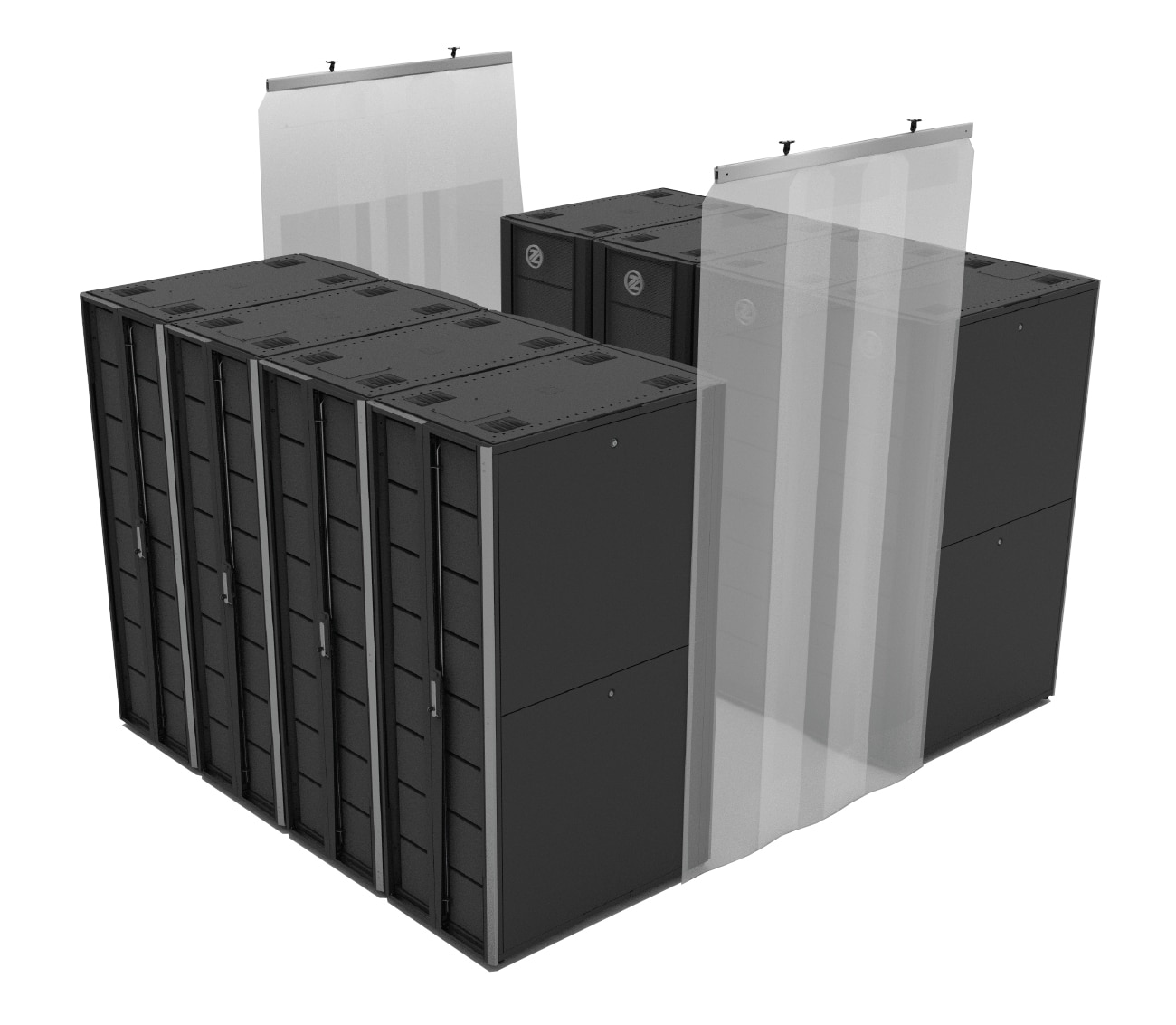

Why Go Modular for Manufacturing?

Permanent cleanroom construction requires months of planning, permitting, and downtime. Production schedules don’t accommodate that timeline. Equipment layouts change. Product lines evolve. Facilities expand.

Modular cleanrooms deploy in days instead of months. Configurations adapt when requirements change. Systems relocate if production moves. You get contamination control on manufacturing timelines, not construction schedules.

| Feature | Modular Cleanrooms | Stick-Built Cleanroom |

| Install Time | Days | Weeks/Months |

| Flexibility | Reconfigurable | Static/Permanent |

| Disruption to Production | Minimal | Often Requires Downtime |

| Upfront Cost | Lower | Higher |

| Long-Term Scalability | High | Low |

Our pre-engineered systems meet ISO and GMP compliance requirements. The modular approach doesn’t compromise contamination control standards. The advantage is deployment speed and operational adaptability.

Cleanrooms Built Around Your Manufacturing Workflow

What is it you want to achieve? The cleanroom configuration follows your manufacturing process, not the reverse.

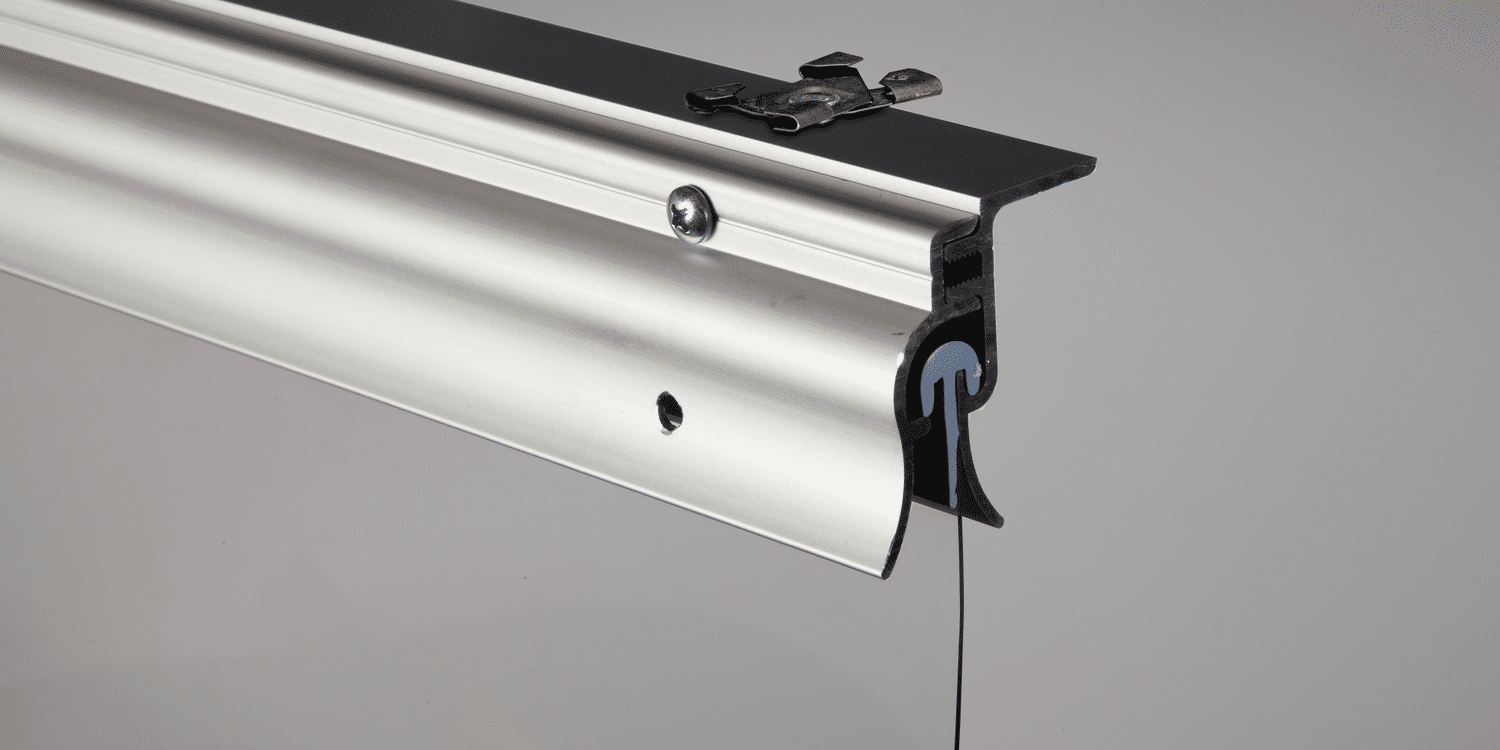

Airflow & Filtration

HEPA or ULPA filters with laminar flow patterns for critical processes. Containment strategies that capture particulates at the source. Pressure differentials that prevent contamination migration between zones.

Zoning & Layout:

Entry vestibules that separate clean and ambient environments. Gowning rooms where required. Pass-through chambers for material transfer without compromising contamination control.

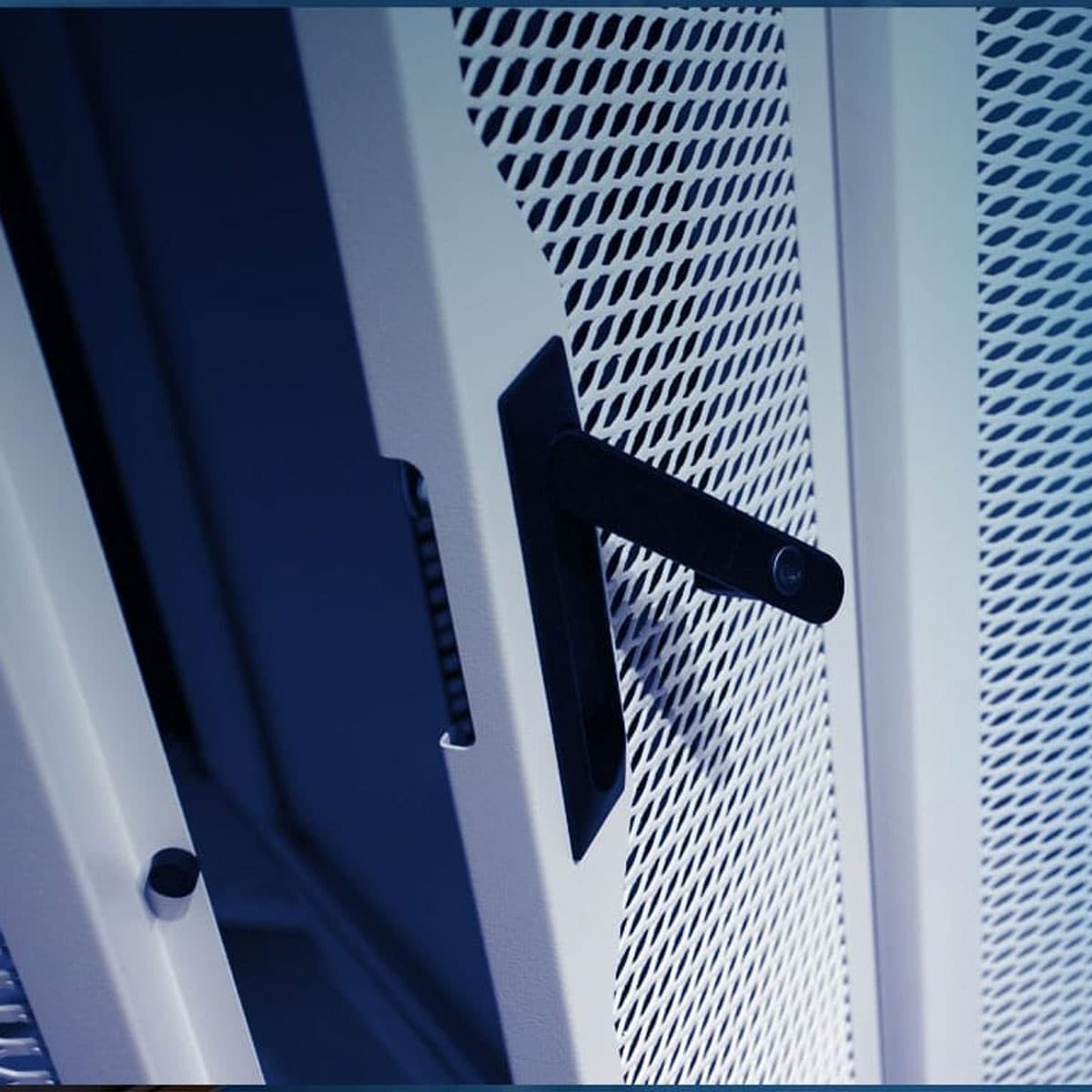

Access Control

Badge entry systems for controlled environments. Clean/dirty pathway separation. Personnel flow patterns that minimize contamination risk.

Materials

Anti-static panels for ESD-sensitive operations. Cleanable surfaces that withstand industrial cleaning protocols. Durable finishes that handle manufacturing environment demands.

Sound Containment

Optional noise-reducing panel systems for equipment isolation. Acoustic performance that protects personnel while maintaining contamination control.

Need deeper technical guidance on cleanroom design? Read our comprehensive cleanroom planning guide.

Product Categories

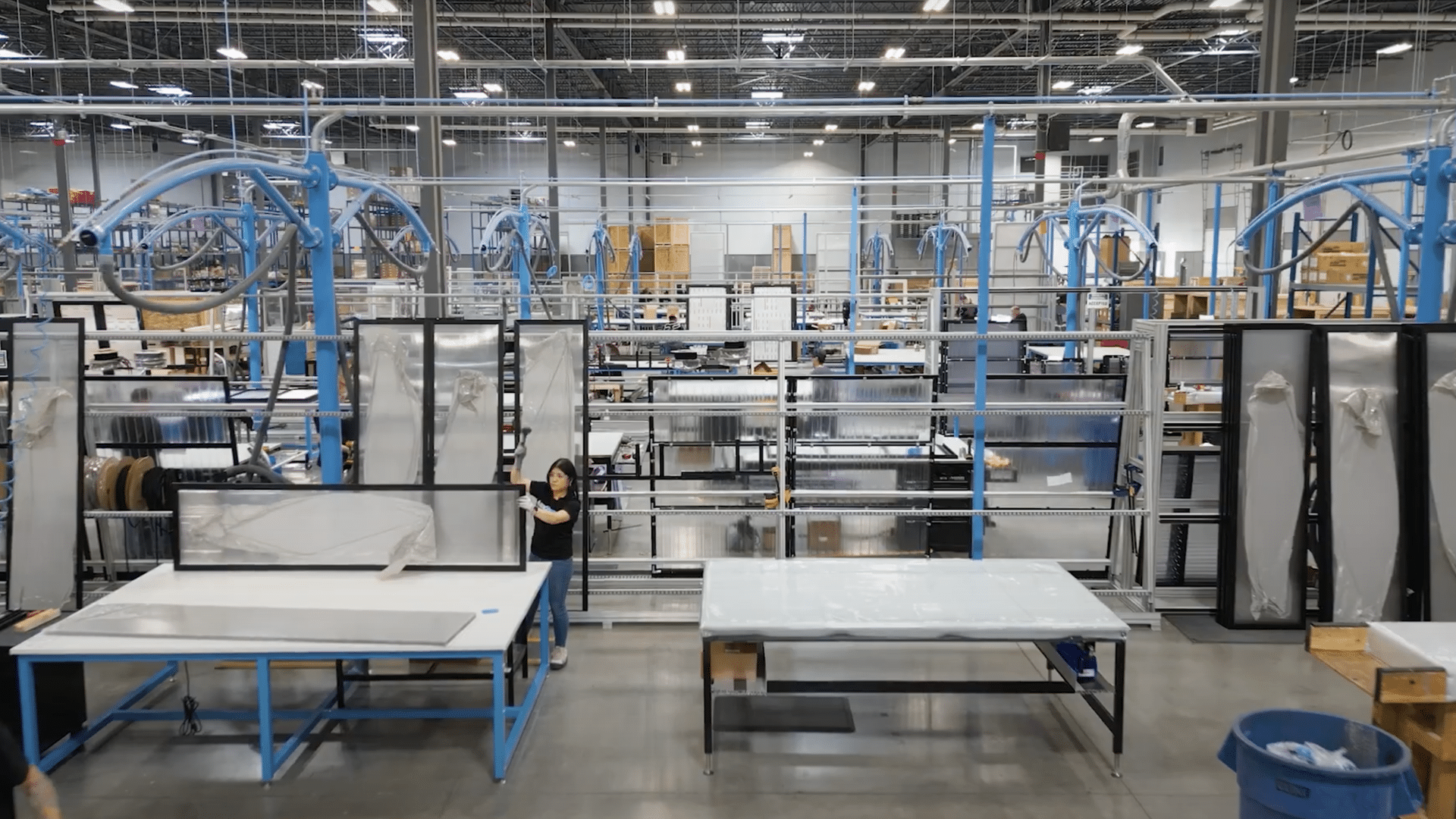

Our comprehensive product portfolio serves critical environments across manufacturing applications like electronics assembly, CNC machining, medical device packaging, and more. With thousands of successful installations worldwide, these modular clean room components have proven their reliability in the most demanding situations.

Modular. Scalable. Trusted. Subzero Engineering.

35+ Years Combined Experience

As one of the leading prefabricated clean room manufacturers, we have engineered contamination control solutions since before modular systems became industry standard.

Proven Results

Our manufacturing cleanroom installations achieve identical contamination control performance to permanent facilities while reducing deployment time by 75%.

Global Support

In-house manufacturing across state-of-the-art facilities with local expertise through regional partners and support teams.

Consultative Approach

We start by asking “What do you want to achieve?” rather than trying to fit existing solutions to your specific requirements.

We’ve deployed manufacturing cleanrooms across automotive, aerospace, electronics, medical device, and pharmaceutical industries. Every installation balances contamination control requirements with operational realities like equipment access, material flow, and production schedules.

Projects range from isolation enclosures around single CNC machines to multi-zone production suites spanning thousands of square feet. Some installations happened during active production cycles with zero downtime. Others involved complete facility reconfigurations where modular systems adapted as layouts evolved.

Defense contractors use our cleanrooms for precision assembly operations in secure facilities. Medical device manufacturers meet FDA compliance without rebuilding existing production areas. Electronics manufacturers protect sensitive components from static and particulates during assembly operations.

Common Questions About Manufacturing Cleanrooms

How long does installation take?

Standard configurations deploy within days depending on size and complexity. Larger multi-zone installations may require additional time but remain dramatically faster than permanent construction. We can work around production schedules to minimize disruption.

Can we install around existing equipment?

Yes. Modular design allows cleanrooms to build around machinery, workstations, and infrastructure already in place. We map existing layouts, identify access requirements, and configure systems that accommodate operational realities.

What are the OSHA requirements for cleanrooms?

OSHA requirements vary by application and industry. Manufacturing cleanrooms must meet workplace safety standards for the specific processes conducted inside them. We help identify applicable requirements during consultation and design compliant solutions.

Are your systems ISO/GMP compliant?

Our modular cleanrooms support ISO classifications and GMP compliance requirements. Systems configure for specific classification levels based on your application. We provide documentation needed for validation and certification processes.

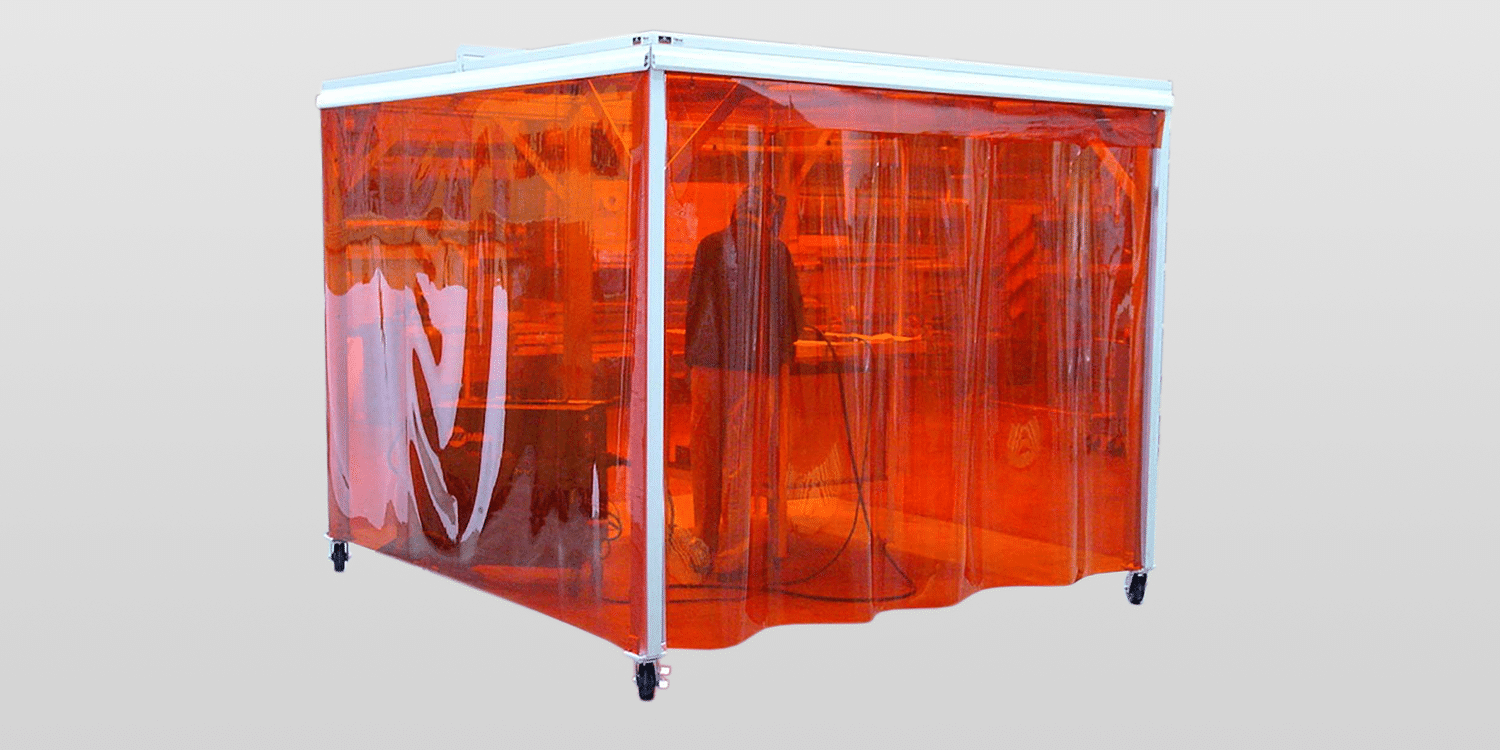

What’s the difference between modular and softwall?

Modular cleanrooms use rigid panel construction with structural frames. Softwall systems use flexible vinyl curtains for lighter contamination control applications. Both approaches work in manufacturing environments depending on your contamination control requirements and operational needs.

Can I expand the cleanroom later?

Complete expandability is fundamental to modular design. Add sections, reconfigure layouts, or increase classification levels as production requirements change. Components integrate seamlessly with existing installations.

Explore More Cleanroom Applications

Subzero Engineering’s Simplex modular clean rooms were developed with custom applications in mind. The possibilities are endless. Whatever the unique requirement, our team brings industry expertise and a proactive approach to solving even the most difficult isolation challenges.

-

Aerospace + Defense

Aerospace + Defense

We understand the complex nature of the aerospace and defense manufacturing industry.

Learn More -

ELECTRONICS MANUFACTURING

ELECTRONICS MANUFACTURING

Modular enclosure solutions for high sensitivity electronics manufacturing environments.

Learn More -

E-LIQUID MANUFACTURING

E-LIQUID MANUFACTURING

We engineer custom e-liquid, e-cigarette, e-juice manufacturing cleanrooms compliant with current FDA regulations.

Learn More -

FOOD PREPARATION

FOOD PREPARATION

Ensure a contamination free environment to process, prep, and package food.

Learn More -

HAZMAT HANDLING

HAZMAT HANDLING

Simplex cleanrooms can be custom designed to deal with the complex handling and storage of hazardous materials.

Learn More -

LASER MANUFACTURING

LASER MANUFACTURING

Airborne contaminants can wreak havoc on lasers; Safeguard your critical laser environment.

Learn More -

Manufacturing Applications

Manufacturing Applications

Simplex cleanrooms and separation products create a variety of solutions for manufacturing facilities.

Learn More -

MEDICAL APPLICATIONS

MEDICAL APPLICATIONS

Simplex cleanrooms can be designed to efficiently Meet and Exceed Industry Regulatory Requirements.

Learn More -

PHARMECEUTICAL COMPOUNDING

PHARMECEUTICAL COMPOUNDING

We have designed numerous cleanrooms for use in the pharmaceutical industry.

Learn More -

TEMPORARY & PORTABLE

TEMPORARY & PORTABLE

Temporary/portable cleanrooms can be designed using hardwall or softwall configurations and can quickly be expanded or relocated.

Learn More