There are numerous considerations when evaluating a cleanroom.

Does your business plan include the development of an area in your plant for clean manufacturing? Are you concerned that you make the right purchase? Do you want to make sure you consider the right factors when you evaluate different models?

There are numerous considerations when evaluating a cleanroom. This article covers the basics.

You may very well need to employ the services of a cleanroom consultant to help you. Here are a few things to keep in mind as you start to consider cleanrooms and controlled environments.

1. What’s the application?

Better quality or better yield is the primary reason for investing in a cleanroom space. It goes straight to your bottom line.

Numerous manufacturing procedures now require a controlled environment in which you limit the amount of dust and dirt in the area of the manufacturing. Medical instrument manufacturing and packaging, electronics and computer manufacturing, food preparation and some military applications are but a few of the instances that have strict requirements for maintaining a clean environment. You need to know the requirement for your specific product or process. If the product you are manufacturing is regulated by a government agency, or you are contracting with a private firm that requires a certain level of clean manufacturing, they should have the cleanroom standards already documented. Check with them first.

There are different levels of cleanrooms. ISO—the International Standards Organization, ranks cleanrooms ISO Class 1 (the cleanest) through ISO Class 9. The lower the ISO rating, the cleaner the environment.

There are different levels of cleanrooms. ISO—the International Standards Organization, ranks cleanrooms ISO Class 1 (the cleanest) through ISO Class 9. The lower the ISO rating, the cleaner the environment. Measurement of contamination is done in “parts-per-cubic-meter.” An ISO Class 6 cleanroom, for example, is rated at 35,200 parts per cubic meter. That means the room can have no more than 35,200 particles greater than .5 micron in size per cubic meter. These are particles that are not visible to the human eye. (As a comparison, a particle of cigarette smoke is between .5 and 2 micron in size. The end of a piece of human hair is about 60 to 100 microns in size).

Particle counts are performed at the work surface height. The pre-filters remove the dirt and dust you can see (call them baseballs and boulders). HEPA filters capture the particles you can’t see with a human eye. A light manufacturing area (defined as an environment that is not generating smoke or oil mist, such as storm window assembly and packaging) with pre-filtration on a HVAC system might be equivalent to an ISO Class 8 room, with 3,520,000 parts per cubic meter that measure greater than .5 micron. This is comparable to room air.

Again, know what the manufacturing requirements are.

2. Know the basic principles behind how a cleanroom works

The majority of cleanrooms, easily more than 90%, are positive-pressure rooms—designed to keep contaminants from entering the room. Air is introduced into the cleanroom, typically at the ceiling level, after passing through a fan-powered HEPA filter that removes particles as small as .5 microns. This creates a pressurized room in which the air pressure in the room is greater than outside the room— hence, positive pressure. The air, and the contaminants in the air, are then pushed down towards the floors, and ultimately pushed out vents in the lower portions of the walls of the room.

This means that air and contaminants from the processes in the room are constantly flowing out of the room. In addition, the air exiting the room, either through vents or when doors are opened, is at a pressure sufficient enough to prevent contaminants from entering via those openings.

Negative-pressure rooms are designed to keep contaminants from leaving the room. A negative pressure room is used in instances of infectious diseases and pathogens, bio-contaminants and some hazardous processes using chemicals, flammables and potentially explosive liquids and powders. Your concern is not what gets into the room, but what gets out.

In a negative pressure room, air is pulled out of the enclosure through reversed HEPA filters, creating a negative pressure inside the room (which prevents contaminants from leaving the room), while air is constantly being drawn in through venting and other openings. The force of the air entering the room prevents contaminants from escaping.

Because they are so prevalent, for purposes of this white paper we will be discussing positive-pressure rooms.

3. ISO standards are the industry norm for rating cleanrooms.

ISO standards were adopted by the industry in 2001. If you do any serious research into ISO standards, you are likely to come across the Federal Standard 209E for cleanrooms, which was the industry norm until ISO standards were developed. The federal standards were officially cancelled by the US Department of Commerce in November 2001, but they are still widely referenced.

“ISO classifications expanded the horizon for classifying clean space,” according to Richard Matthews of Filtration Technology, Inc., in Greensboro, NC, who chaired the ISO board that developed these standards. Here are the Federal standards and their ISO equivalents. Note that ISO created three new levels that the Federal standard did not address.

ISO Class 9 = No comparable Federal standard

ISO Class 8 = Federal standard Class 100,000

ISO Class 7 = Federal standard Class 10,000

ISO Class 6 = Federal standard Class 1,000

ISO Class 5 = Federal standard Class 100

ISO Class 4 = Federal standard Class 10

ISO Class 3 = Federal Standard Class 1

ISO Class 2 = No comparable Federal standard

ISO Class 1 = No comparable Federal standard

Whenever possible, refer to the ISO standards because they are internationally accepted. If you are dealing with partners in other countries, this will make issues much simpler.

4. It’s all about air changes per hour, sometimes

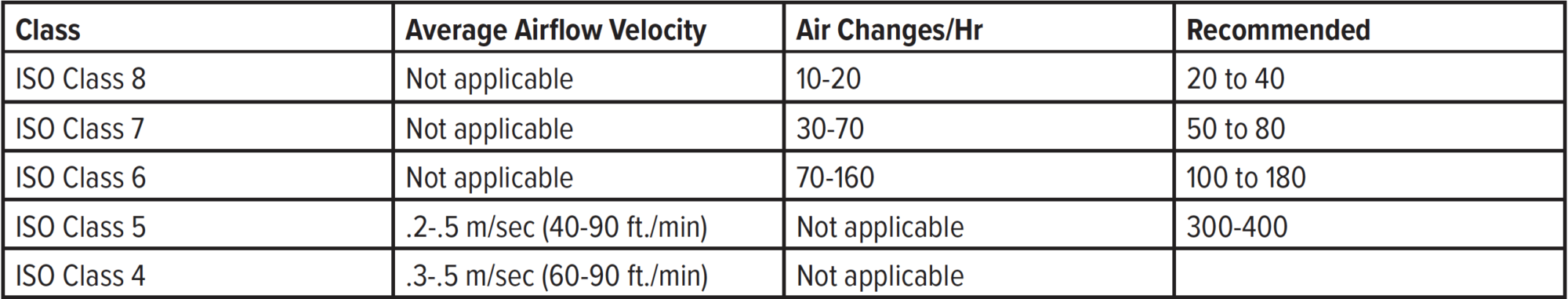

With some exceptions, a cleanroom is a cleanroom is a cleanroom. Achieving a cleaner class of cleanroom is all about airflow. It’s a matter of bringing clean air in through HEPA filters in the ceiling and moving contaminated air out through vents in the walls or floors. The greater the number of HEPA filters and vents, the greater the rate of air change. You can see from this chart what the requirements are:

ISO Class 9 through ISO Class 6 rooms are determined based on air changes per hour. ISO Class 5 through ISO Class 1 rooms are based on the flow of air through the room in meters per second. How are you getting the air into the space and how are you pushng it out? It’s easy to clean the air. The more difficult question is: Are you moving the air out of the area properly? Where does air enter the clean space and how conveniently is it moved out, carrying with it the contaminants from the manufacturing process? Placement of work tables, chairs and equipment becomes more crucial. An item incorrectly placed creates “dead space” where particles are trapped.

These environments are prevalent in micro-electronics and will play a big part in nanotechnology as we get more involved in that industry. At these levels it is very important that you consult with a knowledgeable expert.

5. Every cleanroom has three different states or conditions

Cleanrooms are measured for particulate count at three different levels: As Built, At Rest and Operational. As Built refers to the cleanroom as it is when it is built, empty of any equipment, materials or workers. Cleanrooms are typically certified by the manufacturer as to their level of cleanliness at the As Built level. At Rest refers to the cleanroom once equipment, machinery, furniture and product have been moved in, before the workers. All these elements bring with them sources of contamination, so you can expect a change in particulate count. Finally, there is the Operational level. This refers to the cleanroom when all the equipment and materials are moved in and there are workers in there performing tasks. Again, you are likely to see a change in particulate count. Machinery that performs an excellent function outside of a cleanroom can be a source of pollution inside a cleanroom. Metal shavings, gases and oil mist from pneumatic machinery and vapors from outgassing plastics are all sources of contamination.

Any process that involves friction or movement is going to cause particulation. In order to prevent a drastic increase in contamination at the operational level it is important to adhere to proper protocol and procedures—things like gowning, house cleaning and workflow. If your process must involve machinery, then it may be necessary to further isolate that machine within the cleanroom in order to prevent it from contaminating the rest of the operation. A common solution is to build a cleanroom within the cleanroom using either partitions, or more commonly curtains, to isolate the machine. It may also be necessary to vent that area separately from the rest of the room.

This change in particulate count from As Built, At Rest and Operational levels is another reason that you need to involve a cleanroom expert early on in the process.

6. Modularity

Things change. You can count on that. A cleanroom with a modular design allows the original layout to be expanded without having to rebuild from scratch. Your need for clean manufacturing space will increase or expansion will dictate that you move to larger facilities. Modularity in a cleanroom is important. With a modular design you can, with ease, expand the size of your cleanroom as your needs increase, without having to toss out part or all of your original cleanroom investment. And in the event you move to a new facility, you can disassemble your modular cleanroom and take it with you.

There are also cleanroom designs that incorporate casters so that the enclosure can be easily moved around your factory floor. An example where this might be applicable is an injection mold facility where the manufacturing area is ISO Class 9, but production has an order for an I.V. component that requires an ISO Class 7 environment (an I.V. system has to be manufactured in at least an ISO Class 7 cleanroom). You can create this environment on the factory floor by enclosing the injection-mold machine in a portable cleanroom outfitted with casters and a HEPA unit installed in the ceiling grid. Simply roll the enclosure to the appropriate machine and attach softwall curtains to contain it.

Another advantage to a modular cleanroom is in its tax benefits. A modular cleanroom can be written off in seven years. An existing room within your facility that is transformed into a cleanroom—referred to as “stick-built”—has to be written off over a much longer period of time.

7. Envision future plans

Don’t make the mistake of trying to get along with a minimum of cleanroom space. You will be surprised at the speed your cleanroom needs increase. Better to plan for too much space than not enough.

8. Don’t underestimate air conditioning needs

You might start with three workers in your cleanroom, and then find you need to increase to five or six. All that extra body heat, as well as any heat-producing machinery in your clean area, and that cleanroom quickly starts getting hot and uncomfortable. Also take into consideration that basic cleanroom clothing includes a hair covering, booties and a smock. Anything cleaner than Class 7 requires additional safeguards—masks, beard covers, goggles, etc. It is better to err on the side of too much when planning for air conditioning.

This is where you get into the difference between single-pass and recirculating rooms. A single-pass room is a simple design in which air is pumped into the room from the top and blown out vents at the bottom. If you have to air condition your cleanroom, then you don’t want to just blow that expensive air-conditioned air through the cleanroom and out into a warehouse or other environment where it does little good. A recirculating design uses a double-ceiling system (the space between the ceilings is called a plenum) or a double wall (the space in the walls is called an air chase), or a combination of these two. Cooled, clean air is introduced through the HEPA filters and then flows out of the room, carrying with it any contaminants, into either the air chase or the ceiling plenum, where it is reintroduced into the room after once again passing through the HEPA filters.

When you plan and budget for your cleanroom, consider that installation of a recirculating system for that enclosure is going to be at least 50% of the installation costs. If it is possible to place the cleanroom in an area where air conditioning is already in place that will be a huge money-saver.

9. Not considering all that is needed

It pays to bring in an expert early in the planning process. They can help you troubleshoot airflow problems, the types of testing procedures you must employ, and how to develop cleanroom protocols. A knowledgeable professional will point out things you will not even consider.

It pays to bring in an expert early in the planning process. A knowledgeable professional will point out things you will not even consider

10. Think about process flow

Give some thought to the workflow in your cleanroom. You want materials to come in one end and exit the other, and in the meantime, completing all the necessary assembly and packaging that is needed. The goal is not only to improve productivity and yield but to maintain or improve the speed of the manufacturing process. Again, this is an area where you should employ a consultant.

11. The need for interior isolation.

Every cleanroom ISO Class 7 or cleaner should have an anteroom for gowning, set off from the larger cleanroom with softwall curtains at least. This keeps street dirt from getting into the clean area. Interior isolation is also important in food processing and pharmaceuticals to prevent cross-contamination. A recent Simplex project called for dividers for a vitamin processing operation. If vitamin B12 meanders into the Vitamin C work area, that’s cross-contamination—a huge problem. Cross-contamination can mean manufacturing shutdowns and product recalls and lost profits.

12. Clearance issues

People are often eager to use as much of their space as possible. It is a good idea to give yourself some extra room overhead between the outside ceiling of your cleanroom and the ceiling of your building—Simplex recommends three feet—to allow you to change out the pre-filters, HEPA’s and ULPA’s without a big hassle. The other issue to consider is that without enough clearance, a minimum of six inches, you run the risk of starving your filters for air.

13. More need for clearance

Regarding installation of the room itself, three feet is important all the way around the side walls. It will make the installation easier, as you will have more room to work with. The common space solution is to place the cleanroom against the walls and this is often done. This is great for maximizing the footprint but will make the install more difficult.

The performance of your cleanroom hinges a great deal on the quality of the assembly. Look for a company that supplies the approval drawings with layout and elevations, and also shows the HEPA and lighting layout.

14. Look for a cleanroom with extensive plans and instructions

The performance of your cleanroom hinges a great deal on the quality of the assembly. Look for a company that supplies the approval drawings with layout and elevations, and also shows the HEPA and lighting layout. Look for a manufacturer that supplies installation drawings with every panel marked with a letter or number that corresponds to the panel or part on the drawing. For large cleanrooms and critical applications you might need to consider a specialty contractor knowledgeable in cleanroom construction.

15. Know the difference between a cleanroom and a clean zone and be clear in what you need

Cleanrooms are areas in which the particulate count is measured and controlled. There is a requirement for a specific level of clean. A clean zone is an area within an existing cleanroom that is even cleaner, much like the injection mold operation cited in #4.

There are also areas that a manufacturer may want to isolate, but not have to maintain at a certain ISO level. A recent project Simplex completed involved a manufacturing and warehousing facility where inventory was stored adjacent to the manufacturing area. Dust from the manufacturing process was drifting into the storage area. Although the product was not required to be clean when it was shipped, the manufacturer wanted it to be free from excessive dust—for aesthetic reasons. The goal in this case was isolation, not making the environment clean in the sense of a cleanroom. Simplex installed 300 running feet of industrial opaque vinyl curtain and two industrial strip doors that created a clean zone where product could be stored. Inventory could be shipped without the need for a second cleaning.

16. Establish cleanroom operating procedures and have them documented

Make sure your employees read them, are familiar with them, and follow them—always. The single biggest source of contamination in a clean area is—you guessed it—the worker in that area. If your cleanroom requirements call for gowning and booties, then no employee should ever enter that space without them. To do otherwise contaminates your workplace and sacrifices the integrity of your manufacturing process.

NOTE: Maintaining clean environments can be a complicated and critical task. The information provided here is meant to give the reader a basic understanding of the issues involving the selection of a cleanroom. Simplex recommends that you always consult and work with a cleanroom professional when implementing any sort of isolation procedures in your workplace, laboratory or hospital, thus ensuring that you maintain the highest standards.

Simplex Isolation Systems wishes to thank Richard Matthews of Filtration Technology, Inc., in Greensboro, NC, for his input on this white paper.